PA Series

PA has good overall performance, including mechanical properties, heat resistance, abrasion resistance, chemical resistance and self-lubricating, and low coefficient of friction, a certain degree of flame retardant, easy to process, suitable for glass fibre and other filler filler enhancement modification, improve performance and expand the range of applications.PA's many varieties of PA6, PA66, PA11, PA12, PA6T, PA9T, PA612, PA1010 and so on.

Affiliated Classification:

PA

Key words:

Wangpin

Product Description

PA Series/Polyamide

PA has good overall performance, including mechanical properties, heat resistance, abrasion resistance, chemical resistance and self-lubricating, and low coefficient of friction, a certain degree of flame retardant, easy to process, suitable for glass fibers and other filler filler enhancement modification, improve performance and expand the range of applications.PA's many varieties, there are PA6, PA66, PA11, PA12, PA6T, PA9T, PA6, PA11, PA12, PA6T, PA9T, PA612, PA1010 and so on.

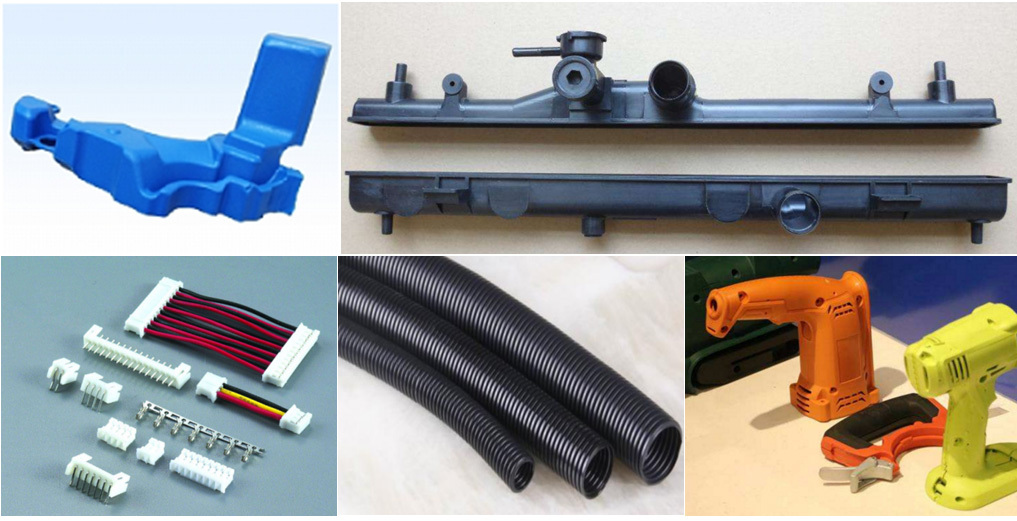

The scope of application of PA modified materials developed and produced by our company:

1, automobile engine periphery, such as cylinder head cover, intake manifold, toothed belt cover and other automobile parts;

2, electrical and electronic, such as connectors, connectors, skeleton, switches and sockets, small appliances;

3, sports equipment, such as roller skates, skis and protective gear, bicycle parts;

4, Packaging and containers, such as aerosol valves, lighters, batteries and so on;

5, Construction and furniture, such as hinges, chair seats, screws and so on;

6, other major applications, such as power tools, rail transportation, machinery parts and so on.

Material Application Examples:

HPA Properties(DATA SHEET) High performance nylon

| Thermal properties | Standard | Unit | NMPA66 B15T | PPA B30 | XPA66-21 | HPA1012 | HPA50BK |

| Heat distortion temperature | GB/T 1634.1-2004 | ℃(1.80 MPa) | 240 | 285 | 67 | 67 | 245 |

| Mechanical properties | Standard | Unit | Value | Value | Value | Value | Value |

| Notched impact strength | GB/T 1843-2008 | KJ/m2 | 6 | 9 | 130 (23℃) | 9.6 (-40℃) | 15 |

| 30 (-40℃) | 10.4(-55℃) | ||||||

| Tensile strength | GB/T 1040.2-2006 | MPa | 120 | 157 | 50 (23℃) | 48 | 245 |

| 80 (-40℃) | |||||||

| Elongation at break | GB/T 1040.2-2006 | % | 15 | 13 | 190 (23℃) | ≥300 | 1.8 |

| 38 (-40℃) | |||||||

| Flexural modulus | GB/T 9341-2008 | Mpa | 6000 | 9000 | 1520 (23℃) | 17 | 17000 |

| 1900(-40℃) | |||||||

| Flexural strength | GB/T 9341-2008 | Mpa | 180 | 230 | 55 (23℃) | 293 | 350 |

| 70 (-40℃) | |||||||

| Rockwell hardness | GB/T 9341-2008 | R | 120 | 120 | 114 | 119 | 120 |

| Rheological properties | Standard | Unit | Value | Value | Value | Value | Value |

| Molding shrinkage (across flow) | GB/T 9341-2008 | % | 0.6 | 0.55 | 1.5 | 1,4 | 0.45 |

| Molding shrinkage (flow) | GB/T 9341-2008 | % | 0.4 | 0.25 | 1.2 | 1.6 | 0.2 |

| Melt flow rate | GB/T 9341-2008 | g/10min | -- | -- | -- | 3.1 | -- |

| Electrical properties | Standard | Unit | Value | Value | Value | Value | Value |

| Volume resistivity | IEC 62631-3 | Ω.cm | ≥1015 | ≥1015 | ≥1015 | ≥1015 | ≥1015 |

| Surface resistivity | IEC 62631-3 | Ω | ≥1014 | ≥1014 | ≥1014 | ≥1014 | ≥1014 |

| Dielectric strength | IEC 60243-1 | KV/mm | 34 | 34 | 34 | -- | 34 |

| Comparative tracking index | IEC 60112 | V | -- | -- | -- | -- | -- |

| Flammability properties | Standard | Unit | Value | Value | Value | Value | Value |

| GWFI /Glow-wire flammability index | IEC 60695-2 | ℃ | -- | -- | -- | -- | -- |

| GWIT /Glow-wire ignition temperature | IEC 60695-2 | ℃ | -- | -- | -- | -- | -- |

| Flammability | UL 94 | - | HB | HB | HB | HB | HB |

| Other properties | Standard | Unit | Value | Value | Value | Value | Value |

| Density | GB/T 1033.1-2008 | g/cm3 | 1.33 | 1.51 | 1.08 | 1.05 | 1.6 |

| Water absorption(24h) | GB/T5486.3—2001 | % | 0.75 | 0.23 | 1.3 | 0.29 | 0.4 |

| Referenceprocessing condition | Value | Value | Value | Value | Value | ||

| Drying | -- | -- | 100-120℃ 4-6H | 110-120℃ 4-6H | 100-120℃ 4-6H | 95-110℃ 4-6H | 110-120℃ 4-6H |

| Mold temperature | -- | -- | 80-90℃ | 80-110℃ | 60-80℃ | 60-80℃ | 100-150℃ |

| Recommended processing temperature | -- | -- | 255-300℃ | 250-300℃ | 260-290℃ | 200-220℃ | 275-320℃ |

| Product Characteristics and Application | Plus Teflon super high abrasion resistance and high finish. Applied to roller skates etc. | Ultra-high heat resistance and high explosion resistance. Used for soldering electronic connectors and automotive intake manifolds. | Ultra-high toughness, -40 degrees low-temperature resistance (replace DuPont ST801). Used in skis and protective gear | Extruded grade long chain nylon, high melting degree, chemical resistance, high pressure burst resistance. Applications in automotive piping systems | High rigidity, high dimensional stability and burst resistance. Used in plastic instead of steel products | ||

Unless otherwise specified, the above data refers to Dry Application Models (DAM) measured at a relative humidity (RH) = 50% and at 23°C in a laboratory environment. The above data are typical values for reference only and are not guaranteed.

The data above was measured under the laboratory environment of 23℃ and RH=50% for DAM status unless otherwise stated , all is typical data, only for reference, not the permit of quality assurance

PA66 Properties(DATA SHEET)

| Thermal properties | Standard | Unit | WZ304FR Non-Reinforced, Halogen Free |

WZG30FR GF30%Non-Reinforced, Halogen Free |

G33C GF33%Non-Reinforced, Halogen Free |

B25K15 Glass-mineral hybrid reinforcement |

G15GZH GF15% Enhanced, Halogen |

| Heat distortion temperature | GB/T 1634.1-2004 | ℃(0.45 MPa) | 244 | 262 | |||

| ℃(1.80 MPa) | -- | 251 | 255 | 255 | 245 | ||

| Mechanical properties | Standard | Unit | Value | Value | Value | Value | Value |

| Notched impact strength | GB/T 1843-2008 | KJ/m2 | 4.5 | 10 | 18 | 10 | 7 |

| Tensile strength | GB/T 1040.2-2006 | MPa | 75 | 135 | 185 | 155 | 115 |

| Elongation at break | GB/T 1040.2-2006 | % | 15 | 14 | 14 | 10 | 14 |

| Flexural modulus | GB/T 9341-2008 | Mpa | 3500 | 10000 | 10000 | 9000 | 4800 |

| Flexural strength | GB/T 9341-2008 | Mpa | 110 | 180 | 270 | 220 | 80 |

| Rockwell hardness | GB/T 9341-2008 | R | 120 | 121 | 121 | 120 | 160 |

| Rheological properties | Standard | Unit | Value | Value | Value | Value | Value |

| Molding shrinkage (across flow) | GB/T 9341-2008 | % | 1.0-1.6 | 0.8 | 0.7 | 0.75 | 0.95 |

| Molding shrinkage (flow) | GB/T 9341-2008 | % | 0.6-0.9 | 0.5 | 0.4 | 0.38 | 0.75 |

| Melt flow rate | GB/T 9341-2008 | g/10min | -- | -- | -- | -- | -- |

| Electrical properties | Standard | Unit | Value | Value | Value | Value | Value |

| Volume resistivity | IEC 62631-3 | Ω.cm | ≥1015 | ≥1015 | ≥1015 | ≥1015 | ≥1015 |

| Surface resistivity | IEC 62631-3 | Ω | ≥1014 | ≥1014 | ≥1014 | ≥1014 | ≥1014 |

| Dielectric strength | IEC 60243-1 | KV/mm | 34 | 34 | 34 | 34 | 34 |

| Comparative tracking index | IEC 60112 | V | -- | -- | -- | -- | -- |

| Flammability properties | Standard | Unit | Value | Value | Value | Value | Value |

| GWFI /Glow-wire flammability index | IEC 60695-2 | ℃ | -- | -- | -- | -- | -- |

| GWIT /Glow-wire ignition temperature | IEC 60695-2 | ℃ | -- | -- | -- | -- | -- |

| Flammability | UL 94 | - | V0 | V0 | HB | HB | HB |

| Other properties | Standard | Unit | Value | Value | Value | Value | Value |

| Density | GB/T 1033.1-2008 | g/cm3 | 1.18 | 1.40 | 1.39 | 1.47 | 1.25 |

| Water absorption(24h) | GB/T5486.3—2001 | % | 1.1 | 0.6 | 0.7 | 0.7 | 1.0 |

| Referenceprocessing condition | Value | Value | Value | Value | Value | ||

| Drying | -- | -- | 100-120℃ 4-6H | 100-120℃ 4-6H | 100-120℃ 4-6H | 110-120℃ 4-6H | 100-120℃ 4-6H |

| Mold temperature | -- | -- | 80-100℃ | 80-100℃ | 80-100℃ | 100-130℃ | 80-100℃ |

| Recommended processing temperature | -- | -- | 250-280℃ | 250-280℃ | 250-300℃ | 260-310℃ | 250-290℃ |

| Product Characteristics and Application | Halogen-free flame retardant, electrical properties. Used in terminal blocks, electronic connectors | 30% glass fiber reinforced halogen-free flame retardant, electrical properties. Applied to all kinds of electronic and electrical components | 33% glass fiber reinforced, good mechanical and electrical properties. Used in automobile shifter base, power tool parts, etc. | 25% glass fiber + 15% mineral reinforcement, low warpage, long term heat resistance. Used in automobile engine hood cover, etc. | 15% glass fiber reinforced. Used in automotive and mechanical parts | ||

Unless otherwise specified, the above data refers to Dry Application Models (DAM) measured at a relative humidity (RH) = 50% and at 23°C in a laboratory environment. The above data are typical values for reference only and are not guaranteed.

The data above was measured under the laboratory environment of 23℃ and RH=50% for DAM status unless otherwise stated , all is typical data, only for reference, not the permit of quality assurance

PA6 Properties(DATA SHEET)

| Thermal properties | Standard | Unit | WZ104FR Non-Reinforced, Halogen Free |

ZG30FR GF30% reinforced, halogen free |

G33C GF 33 per cent enhancement |

GZH101FR Extrusion Grade, Halogen |

X32 Super Tough |

| Heat distortion temperature | GB/T 1634.1-2004 | ℃(0.45 MPa) | 205 | 224 | 224 | 160 | 150 |

| ℃(1.80 MPa) | 215 | 215 | 57 | 55 | |||

| Mechanical properties | Standard | Unit | Value | Value | Value | Value | Value |

| Notched impact strength | GB/T 1843-2008 | KJ/m2 | 6 | 10 | 12 | 8 | 116 |

| Tensile strength | GB/T 1040.2-2006 | MPa | 75 | 125 | 170 | 60 | 49 |

| Elongation at break | GB/T 1040.2-2006 | % | 20 | 14 | 12 | 50 | 150 |

| Flexural modulus | GB/T 9341-2008 | Mpa | 3000 | 8000 | 8800 | 2850 | 1400 |

| Flexural strength | GB/T 9341-2008 | Mpa | 105 | 180 | 245 | 90 | 64 |

| Rockwell hardness | GB/T 9341-2008 | R | 120 | 120 | 120 | 120 | 114 |

| Rheological properties | Standard | Unit | Value | Value | Value | Value | Value |

| Molding shrinkage (across flow) | GB/T 9341-2008 | % | 0.8 | 0.8 | 0.85 | 0.8 | 1.37 |

| Molding shrinkage (flow) | GB/T 9341-2008 | % | 0.75 | 0.5 | 0.45 | 0.75 | 1.29 |

| Melt flow rate | GB/T 9341-2008 | g/10min | -- | -- | -- | -- | -- |

| Electrical properties | Standard | Unit | Value | Value | Value | Value | Value |

| Volume resistivity | IEC 62631-3 | Ω.cm | ≥1015 | ≥1015 | ≥1015 | ≥1015 | ≥1015 |

| Surface resistivity | IEC 62631-3 | Ω | ≥1014 | ≥1014 | ≥1013 | ≥1014 | ≥1013 |

| Dielectric strength | IEC 60243-1 | KV/mm | 34 | 34 | 22 | 34 | 15 |

| Comparative tracking index | IEC 60112 | V | -- | -- | -- | -- | -- |

| Flammability properties | Standard | Unit |

Value | Value | Value | Value | Value |

| GWFI /Glow-wire flammability index | IEC 60695-2 | ℃ | -- | -- | -- | -- | -- |

| GWIT /Glow-wire ignition temperature | IEC 60695-2 | ℃ | -- | -- | -- | -- | -- |

| Flammability | UL 94 | - | V0 | V0 | HB | V0 | HB |

| Other properties | Standard | 单位 Unit |

Value | Value | Value | Value | Value |

| Density | GB/T 1033.1-2008 | g/cm3 | 1.18 | 1.47 | 1.47 | 1.30 | 1.08 |

| Water absorption(24h) | GB/T5486.3—2001 | % | 1.7 | 1.1 | 1.1 | 0.7 | 0.7 |

| Referenceprocessing condition | Value | Value | Value | Value | Value | ||

| Drying | -- | -- | 100-120℃ 4-6H | 100-120℃ 4-6H | 100-120℃ 4-6H | 100-120℃ 4-6H | 100-120℃ 4-6H |

| Mold temperature | -- | -- | 80-100℃ | 80-100℃ | 80-100℃ | 80-100℃ | 80-100℃ |

| Recommended processing temperature | -- | -- | 215-260℃ | 210-270℃ | 210-270℃ | 215-250℃ | 200-270℃ |

| Product Characteristics and Application | Halogen-free flame retardant, electrical properties. Application: terminal blocks, sockets and other electrical and electronic components. | 30% glass fibre reinforced halogen-free flame retardant, electrical properties. Used in electrical and electronic components such as terminal blocks and sockets. | Excellent flame retardancy, heat and water resistance. Applied to all kinds of electronic and electrical shells | Flame retardant, good flexibility and thermal stability, good melt strength extrusion type. Applications : Bellows, electrical and electronic fittings, etc. | Extremely excellent impact resistance at low temperatures (-40°C). Used in products such as refrigerated wheels | ||

The data above was measured under the laboratory environment of 23℃ and RH=50% for DAM status unless otherwise stated , all is typical data, only for reference, not the permit of quality assurance

Related Products

Message