pp plastic series

pp plastic is a thermoplastic resin produced by the polymerisation of propylene. According to the methyl arrangement position is divided into isotactic polypropylene (isotactic polypropylene), atactic polypropylene (atactic polypropylene) and intermediate polypropylene (syndiotactic polypropylene) three. Methyl arranged in the main chain of the molecule on the same side of the isotactic polypropylene, if the methyl disorderly arranged in the main chain of the molecule on both sides of the atactic polypropylene, when the methyl alternately arranged in the main chain of the molecule on both sides of the isotactic polypropylene. General industrial production of polypropylene resin, isometric structure content of about 95%, the rest of the atactic or intermediate polypropylene. Industrial products are mainly composed of isoforms. Polypropylene also includes copolymers of propylene and small amounts of ethylene. It is usually a translucent colourless solid, odourless and non-toxic. Due to the regular structure and high degree of crystallisation, so the melting point can be as high as 167 ℃. Heat and corrosion resistance, products can be sterilised by steam is its outstanding advantage. Small density, is the lightest general-purpose plastics. Disadvantages are poor low-temperature impact resistance, easier to age, but can be overcome by modification.

Affiliated Classification:

pp plastic

Key words:

Wangpin

Product Description

Polypropylene

PP polypropylene is a thermoplastic resin produced by the polymerisation of propylene. According to the methyl arrangement position is divided into isotactic polypropylene (isotactic polypropylene), atactic polypropylene (atactic polypropylene) and intermediate polypropylene (syndiotactic polypropylene) three.

Methyl arranged in the main chain of the molecule on the same side of the isotactic polypropylene, if the methyl disorderly arranged in the main chain of the molecule on both sides of the atactic polypropylene, when the methyl alternately arranged in the main chain of the molecule on both sides of the isotactic polypropylene. General industrial production of polypropylene resin, isometric structure content of about 95%, the rest of the atactic or intermediate polypropylene. Industrial products are mainly composed of isoforms. Polypropylene also includes copolymers of propylene and small amounts of ethylene. It is usually a translucent colourless solid, odourless and non-toxic. Due to the regular structure and high degree of crystallisation, so the melting point can be as high as 167 ℃. Heat and corrosion resistance, products can be sterilised by steam is its outstanding advantage. Small density, is the lightest general-purpose plastics. Disadvantages are poor low-temperature impact resistance, easier to age, but can be overcome by modification.

The scope of application of PP modified materials developed and produced by our company:

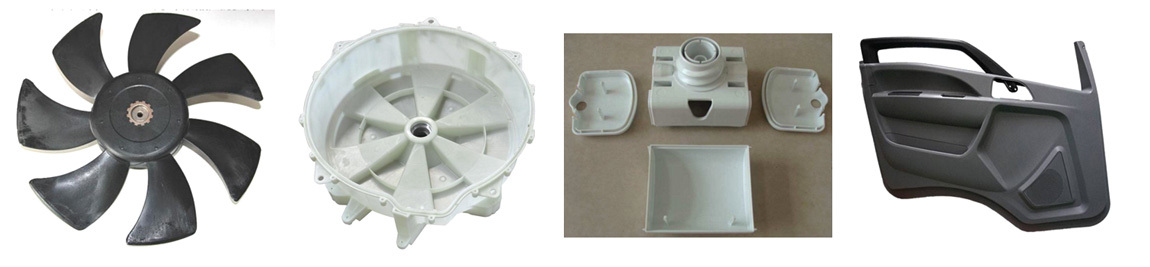

1, household appliances: air conditioner parts, refrigerator parts, washing machine parts, fan parts, etc.;

2, car: door panels, bumpers, wings, etc..

Material Application Examples:

PP Physical Property Sheet (DATA SHEET)

| Thermal properties | Standard | Unit | K1011G30 30% glass fibre reinforced |

K1011G20R Halogen free, 20% glass fibre reinforced |

K1011FR Halogen free, 20% glass fibre reinforced |

K1011EPDM weathering grade |

| Heat distortion temperature | GB/T 1634.1-2004 | ℃(1.80 MPa) | 155 | 145 | -- | -- |

| ℃(0.45 MPa) | -- | -- | 110 | 90 | ||

| Mechanical properties | Standard | Unit | Value | Value | Value | Value |

| Notched impact strength | GB/T 1843-2008 | KJ/m2 | 10 | 4 | 20 | 32 |

| Tensile strength | GB/T 1040.2-2006 | MPa | 80 | 74 | 20 | 22 |

| Elongation at break | GB/T 1040.2-2006 | % | 18 | 18 | 50 | 320 |

| Flexural modulus | GB/T 9341-2008 | Mpa | 5500 | 5500 | 1800 | 1000 |

| Flexural strength | GB/T 9341-2008 | Mpa | 105 | 110 | 30 | 24 |

| Rockwell hardness | GB/T 9341-2008 | R | 105 | 105 | 100 | 98 |

| Rheological properties | Standard | Unit | Value | Value | Value | Value |

| Molding shrinkage (across flow) | GB/T 9341-2008 | % | 0.4 | 0.4 | -- | -- |

| Molding shrinkage (flow) | GB/T 9341-2008 | % | 0.5 | 0.5 | 0.1-0.5 | 0.1-0.5 |

| Melt flow rate | GB/T 9341-2008 | g/10min | 15 | 15 | 18 | 20 |

| Electrical properties | Standard | Unit | Value | Value | Value | Value |

| Volume resistivity | IEC 62631-3 | Ω.cm | ≥1017 | ≥1017 | ≥1017 | ≥1017 |

| Surface resistivity | IEC 62631-3 | Ω | -- | -- | -- | -- |

| Dielectric strength | IEC 60243-1 | KV/mm | 40 | 40 | 40 | 40 |

| Comparative tracking index | IEC 60112 | V | -- | -- | -- | -- |

| Flammability properties | Standard | Unit | Value | Value | Value | Value |

| GWFI /Glow-wire flammability index | IEC 60695-2 | ℃ | -- | 960 | 960 | -- |

| GWIT /Glow-wire ignition temperature | IEC 60695-2 | ℃ | -- | -- | -- | -- |

| Flammability | UL 94 | - | HB | V0 | V0 | HB |

| Other properties | Standard | Unit | Value | Value | Value | Value |

| Density | GB/T 1033.1-2008 | g/cm3 | 1.15 | 1.13 | 1.08 | 0.98 |

| Water absorption(24h) | GB/T5486.3—2001 | % | 0.01-0.03 | 0.01-0.03 | 0.01 | 0.01 |

| Referenceprocessing condition | Value | Value | Value | Value | ||

| Drying | -- | -- | 90-100℃/1-2H | 90-100℃/1-2H | 80-90℃/4-6H | 80-90℃/4-6H |

| Mold temperature | -- | -- | 70-90℃ | 70-90℃ | 60-80℃ | 60-80℃ |

| Recommended processing temperature | -- | -- | 200-240℃ | 200-240℃ | 180-240℃ | 180-240℃ |

| 产品特点及市场应用 Product Characteristics and Application |

High strength, high heat resistance, excellent processability, not easy to warp and deformation and other characteristics. Applied to various parts of electronic and electrical appliances | High strength, efficient flame retardant 960 degree scorching wire, electrical properties, heat resistance. Applied to electronic and electrical products |

Highly efficient flame retardant 960 degree scorch wire, no-drop performance. Used in all kinds of electronic and electrical housings

|

Excellent weather resistance, high strength, high dimensional stability, used in automotive door panels, insurance carriers, wings and other parts. | ||

The data above was measured under the laboratory environment of 23℃ and RH=50% for DAM status unless otherwise stated , all is typical data, only for reference, not the permit of quality assurance

Related Products

Message