Thermally Conductive PA Material

PA has good overall performance, including mechanical properties, heat resistance, abrasion resistance, chemical resistance and self-lubricating, and low coefficient of friction, a certain degree of flame retardant, easy to process, suitable for enhanced modification with glass fibers and other fillers filled with modified, coupled with good electrical insulation capacity and chemical resistance, so that the nylon used in a wide range of applications, our company R & D and production of the model number: HP5510N thermal conductivity PA plastic Not only has the heat transfer properties of metals and ceramics, but also retains the advantages of ordinary plastics in the design, performance and cost, with uniform heat dissipation, light weight, easy molding and processing, low coefficient of thermal expansion, low molding shrinkage, low operating temperatures and improve the design of the freedom of characteristics, widely used in all walks of life;

Affiliated Classification:

Thermally Conductive PA Plastic

Key words:

Wangpin

Product Description

PA Series/Polyamide

PA has good overall performance, including mechanical properties, heat resistance, abrasion resistance, chemical resistance and self-lubricating, and low coefficient of friction, a certain degree of flame retardant, easy to process, suitable for enhanced modification with glass fibers and other fillers filled with modified, coupled with good electrical insulation and chemical resistance, so that the nylon used in a wide range of applications, our company research and development and production of the model number: HP5510N thermally conductive PA plastic Not only has the heat transfer properties of metals and ceramics, but also retains the advantages of ordinary plastics in the design, performance and cost, with uniform heat dissipation, light weight, easy molding and processing, low coefficient of thermal expansion, low molding shrinkage, low operating temperatures and improve the design of the freedom of characteristics, widely used in all walks of life;

Material Application Examples:

Properties of Insulation and Thermal Conductivity HP5510N

| sports event | method of measurement | prerequisite | flat | HP5510N |

| Thermal conductivity | Laser Flash (Refer to ASTM E1461) | 1mmt | W/m・K | 2.8 |

| 1mmt | 1.0 | |||

| S/pecific Gravity | GB/T 1033.1-2008 | 23℃ | g/cm3 | 1.8 |

| IZOD/Izod Impact Stre. Notched | GB/T 1843-2008 | 23℃ | KJ/m2 | 7 |

| Tensile Str,Yield | GB/T 1040.2-2006 | 23℃ | Mpa | 80 |

| Tensile Elongation,Break | 23℃ | % | 2 | |

| Deflection Temperature | GB/T 1634.1-2004 | 1.8MPa | ℃ | 210 |

| Flammabilty | UL94 | 2.0mm | - | 2.0mm(V-0) |

| Insulation failure strength | ASTM D149 | 23℃(AC50Hz) | kV/mm | 20 |

| Standard molding conditions: Molding temperature 260゜C Mold temperature 100゜C Injection pressure 150MPa Injection speed 150mm/s | ||||

Forming condition

1. HP5510N thermally conductive plastic must be dried before molding.

1) Because HP5510N thermally conductive plastic is a resinous polyester, if it is molded in a wet condition, it will be hydrolyzed, which will seriously damage the mechanical properties.

Moisture will also cause changes in the fluidity of the material, resulting in sticking to the mold and burrs during molding.

Standard drying conditions: 140℃×5hr

2) When drying pellets before molding, any one of the following drying equipment is required:

①Hopper dryer -------- dehumidification type

② Shelf dryer ------ dehumidification type

2. Mold to be suitable for the design

1) The gate size is too small, there is a risk of scorching due to the heat generated by the cutting.

2) Since the shrinkage rate of molding is less than that of the mixture filled with glass fiber, it is necessary to adopt a suitable molding shrinkage rate.

Proposed forming condition

Table. Recommended conditions for injection molding

| model number | Recommended Setting Conditions (°C) | ||||

| Nozzle temperature | Paragraph 1 | Paragraph 2 | Paragraph 3 | Mold surface temperature | |

| HP5510N | 260 | 250 | 240 | 230 | 100 (90~115) |

<Precautions

In order to avoid deterioration of the resin, it is recommended to use an injection molding machine with a cylinder capacity to molded product capacity ratio of about 2 to 5.

Due to its thermal conductivity, HP5510N thermally conductive plastic cures faster than ordinary resins, so it is recommended to use high-speed, high-pressure injection and high-temperature molds.

High-speed, high-pressure injection and high-temperature molds are recommended, as well as the recommended holding pressure changeover position is 2 to 5mm.

If the fluidity is not enough, increase the injection pressure and injection speed to the extent that no scorching occurs.

If increasing the injection pressure and injection speed does not solve the problem of fluidity, increase the setting temperature of the nozzle N and cylinder H1 by 10℃.

*The above data are typical values.

Recycling process

Basic matters:

Basically, the ratio of recycled material should be kept below 20%.

The part that can be reused as recycled material is only the main flow channel and the manifold.

The ideal ratio of recycled material to Virgin material varies depending on the shape of the body and the physical properties required by the customer.

The ideal mixing ratio is determined by first molding the material at an arbitrary ratio, then testing the physical properties of the form and confirming that there is no problem with the practicality of the mixing.

Compliance

Recycled materials that are discolored (e.g. burned) cannot be mixed with Virgin materials.

Recycled materials in powder form (crushed to powder) cannot be mixed with Virgin materials.

Recycled material must be dried again (140 degrees Celsius, 5 hours) before feeding.

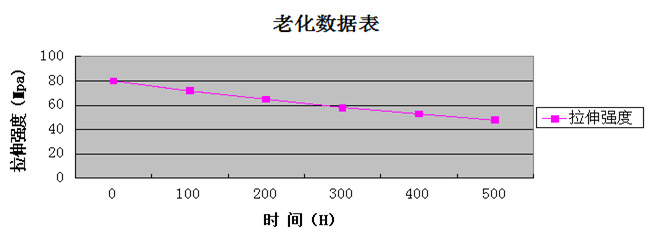

Accelerated weathering test / Weathering test

| tensile strength | Initial (0H) | Mpa | 80 |

| After 500H. (Condition: *1) | Mpa | 48 | |

| Physical retention rate | % | 60% | |

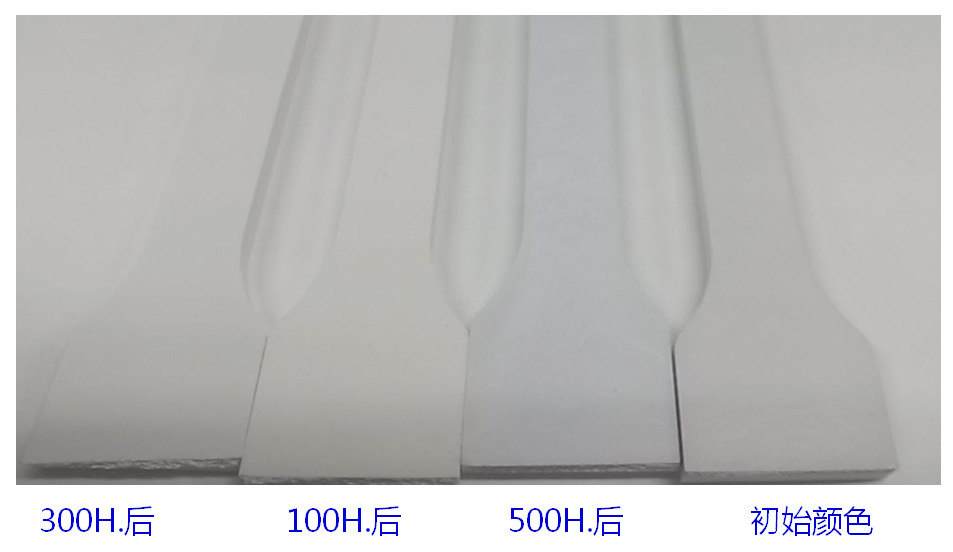

| aberration of color | ΔE | 8.1 |

*1: Xenon arc radiation (①Accumulated radiation: 324MJ/m2, ②Temperature: 60℃, ③Rain (with rain))

Test equipment: Super Xenon Weather Meter 【Suga Test Instruments Co., Ltd.(SX2D-75)

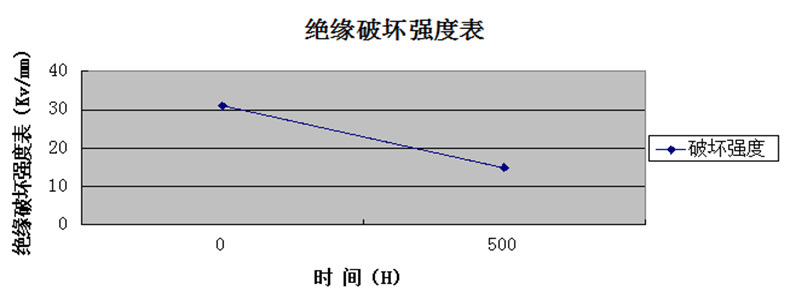

Electrical Characteristics (High Temperature, High Humidity) Test/Electrical Characteristics (High Temperature, High Humidity) Test

| HP5510N | |||

| 绝缘破坏 强度 | 初期(0hr) | kv/mm | 31 |

| 500hrs后 | kv/mm | 15 | |

| 物性保持率 | % | 49% | |

Test conditions: ① Temperature: 85℃, ② Humidity: 85%, ③ Time: 500hrs. Sample piece (thickness): 2mm (t)

Color change

Related Products

Message